Suspended Ceiling Hanger Wire Spacing

300mm 45 0 45 0 300mm 1 80mtr.

Suspended ceiling hanger wire spacing. These recommendations are intended for suspended ceilings and related components in areas that require resistance to the effects of earthquake motions. Astm e580 section 3 2 all wire ties are to be three tight turns around themselves within three inches. 250 dwsc splice clip the splice clip is used to connect cut ends of grid components. Threaded hangers have a pointed screw end for tapping into wood.

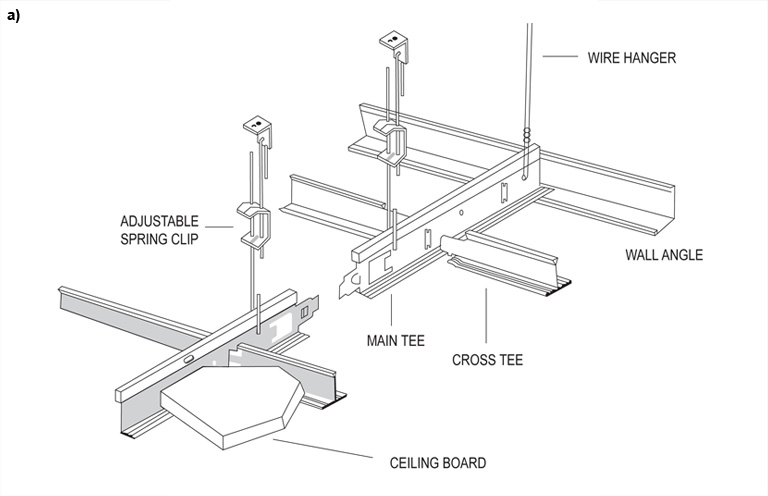

9 fire resistive assemblies. For screws and hanger wire. Size is perfect for attaching drop ceiling hanger wire to wood joists. The ceiling system is made up of armstrong panels either 2 x 4 or 2 x 2 which are supported by a suspension system main beams cross tees and hangers and perimeter molding.

Screw on hangers have an unthreaded hole for mounting with a fastener. These screws are easy to use and durable. Requires actual 48 inch opening. It can also.

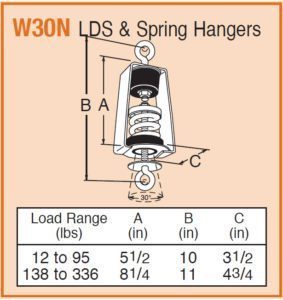

For residential projects tie the support wire around the fastener with at least 2 full wraps using 2 strands of 18 gauge wire. 48 50 72 on center spacing. For technical drawings and 3 d models click on a part number. Installation of hangers ceiling soffit duct section threaded rod hanger wire vertical support slotted bar main tee for suspending the ceiling.

Attach these light duty hangers to ceilings and walls. Slope 1 in 1 8mtr in any plane if more use counter splaying wires step 5. They have a stiff wire for supporting suspended ceilings lighting fixtures and other lightweight material. Along the main tee.

Fixture is level with drywall 5. Can achieve heavy duty load carrying capacity values. The suspend it eye lag screws for wood joists 100 pack are specifically designed for installation of drop ceilings. Suspended from flange kit 4.

Hanger wires are typically spaced 4 ft. Twelve gauge hanger wire spaced 4 ft on center figure 1. In all cases at least 2 full wraps must be completed. 6 spacing on mains results in cost savings of 10 15 by reducing material hanger wire and installation time simplify your curved drywall installations with our pre notched main beams to create the radius you need.

It is very important that the wires are installed into a solid structure because drywall grid systems need to be able to support a large load. The support wires are spaced 4 lineal feet apart down the length of the main and 4 apart between each main as well. Reducing the hanger wire spacing on intermediate duty main tees from 4 ft. Reducing the hanger wire spacing on intermediate duty main tees can achieve heavy duty load carrying capacity values but.

Hanger wire can be suspended for ceiling installation. The integrity of the entire suspended ceiling depends on the hangers commonly wires which are used to support the suspension system main beams.